SPAX Hex Washer Head HCR PowerLags

Diameter

Length

Package Size

SPAX Hex Washer Head HCR PowerLags

1/2" / 5" / Individual PowerLag (1 QTY)

JMP Wood Brooklyn

760 E 96th St

Brooklyn NY 11236

United States

JMP Wood Carteret

1100 Milik Street

Carteret NJ 07008

United States

SPAX Hex Washer Head PowerLags® with HCR® coating are intended for wood to wood connections in exterior structural applications. These fasteners are designed with a hex head conventional driver system along with a built in washer for applications requiring superior pull-down force. Often used in high torque applications.

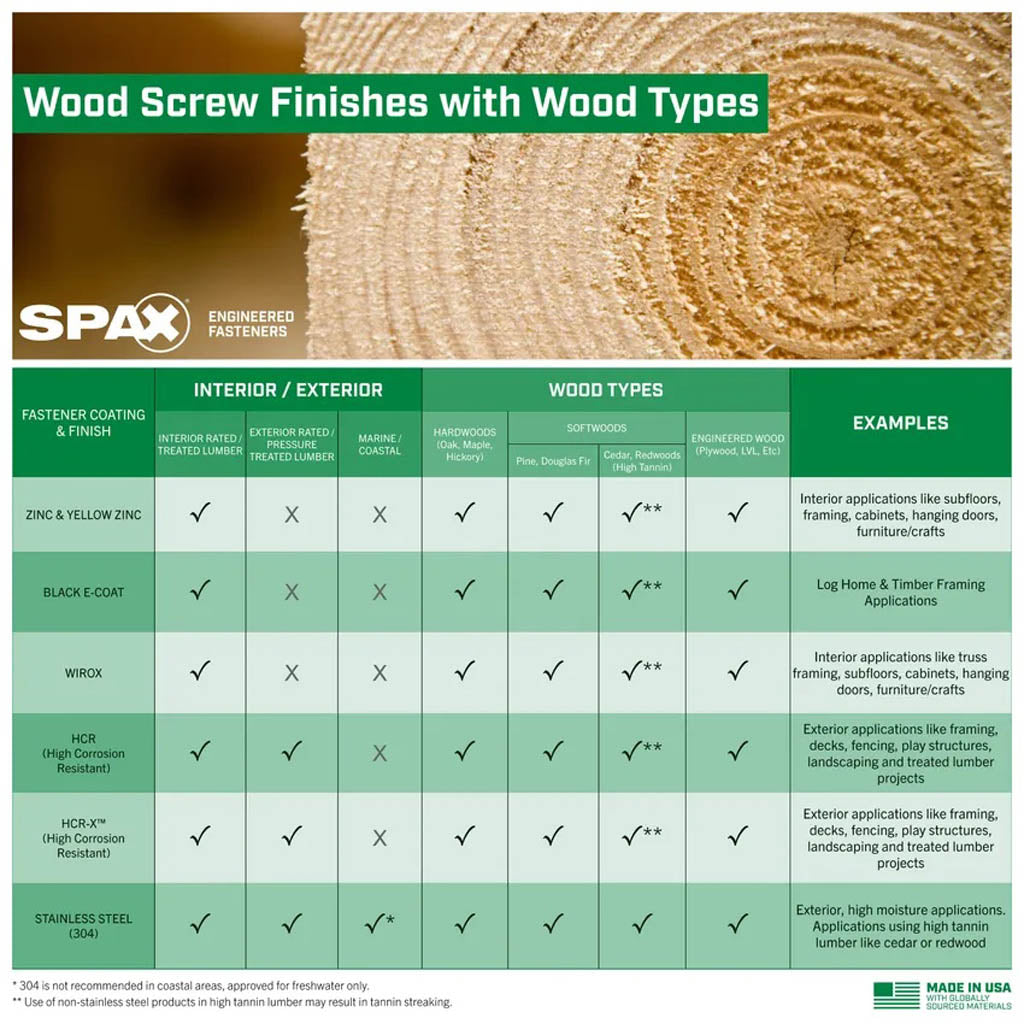

Material and Coating:

Cold-rolled carbon steel wire heat treated for strength and durability and plated with an HCR® (High Corrosion Resistance) double barrier coating. HCR® is tested and recognized for use in ground contact pressure treated lumber for exterior, freshwater general construction applications. (e.g., AWPA UC1-UC4A, UCFA)

Features & Specs:

PowerLags® are the ideal replacement for conventional lags!

- No pre-drilling required (1/4" and 5/16"). Note: Lead holes of 11/64" (0.172") diameter is required for 3/8" and 13/64" (0.203") diameter is required for 1/2" PowerLags®

- Heat treated for strength and durability

- IRC / IBC Code Compliant DrJ TER No. 1912-07 Structural Fastener Properties

- Patented thread serrations require up to 40% less driving torque to increase installation speed while helping prevent cracking in logs

- Built-on washer head designs eliminate the need and extra cost of a separate washer

- Fastener length stamp on the head provides convenient identification without measuring and aids on-site inspections

- Sold in job-friendly package quantities, including bulk pails

Typical Applications:

- Deck ledger to band joist attachment

- Exterior treated lumber pergolas and gazebos

- Landscaping timber

- Outdoor furniture

- Exterior fencing

- Decorative applications

SPAX engineered fasteners are the most advanced fastener product on the market.

They're tested under the toughest scenarios, including structural integrity and breakage and corrosion for code-compliance, creating more confidence in every connect.